In 2009, Drew Hinton joined the fire service in Louisville and immediately fell in love with hazmat. He built up a file of hazmat certs. He served as environmental, health, safety and sustainability manager for a global chemical company, where he built the organization’s first internal hazmat teams. And in February 2020, Hinton started Arrow Safety, LLC. Arrow travels nationwide conducting various site-specific courses for clients in industries ranging from manufacturing and construction to oil and gas, to aviation and automotive.

He is a Certified Hazardous Materials Manager and is IFSAC-certified in hazardous materials. He serves on the Institute of Hazardous Materials Management’s nominations committee, the HazMat Society’s training and education committee and the Barren County (Ky.) LEPC.

What type of students do you train and what facilities do you have at your disposal?

We train students in nearly every industry. However, the majority of our hazmat-related training courses are involved in manufacturing and have large quantities of hazardous materials on-site. This can range from chlorine gas and anhydrous ammonia to hydrofluoric acid and sulfuric acid. We have also conducted various hazmat training courses at fire departments across the United States, as well as at universities.

Nearly all our training on the manufacturing side involves internal hazmat teams that have been created to respond to site-specific emergencies of varying levels. Our training courses continuously have a mixture of experienced and inexperienced hazmat team members, all with different backgrounds, including engineering, maintenance, operations, etc.

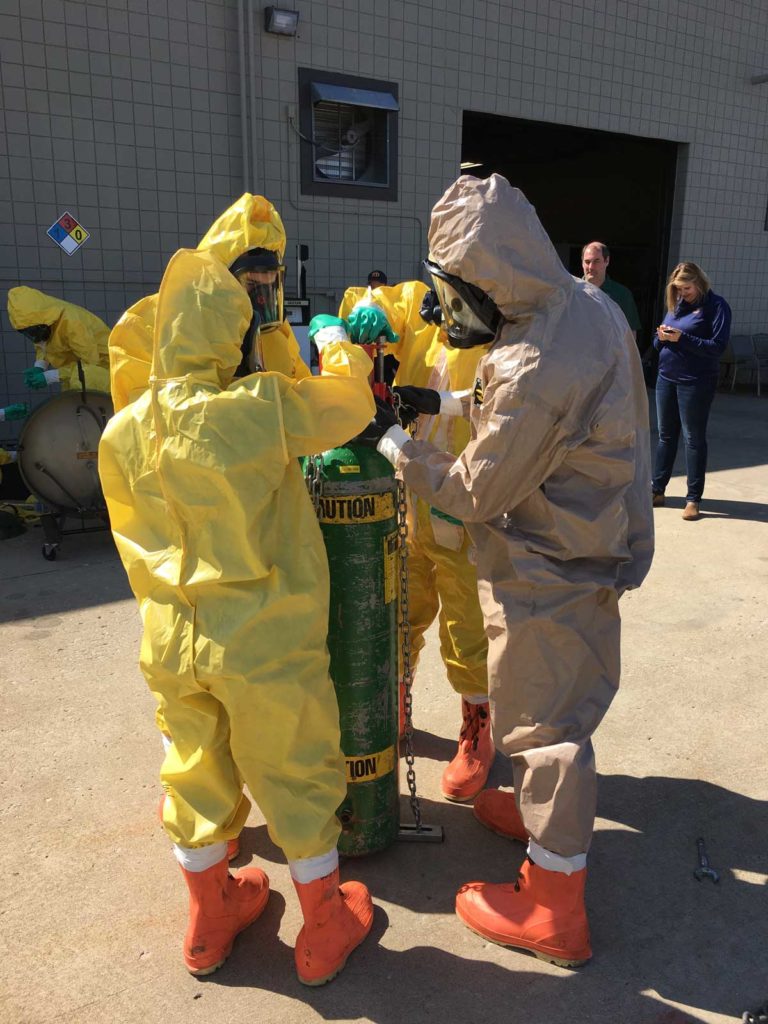

All our trainings are conducted at the customer’s site so that we can focus on their site-specific hazards, use the equipment that they are going to be using during an emergency and make it as realistic as possible. We bring our own resources to show to students in case they are looking for new ideas or if we need additional resources. Our trainings use a custom-built leak prop to simulate leaking valves and flanges, as well as smoke machines to add a more realistic feel to the emergency. We always work with the customer in the weeks and months leading up to the training to ensure we incorporate all site-specific procedures into the training, including using internal notification systems during our hands-on scenarios, whether it be via a PA system, mobile app notification system or any other methods of communicating the emergency to designated responders.

How do you mix up the training scenarios so they don’t become predictable or stale?

While some of the classroom lectures may cover the same material so that we cover the required topics listed in OSHA’s HAZWOPER standard (1910.120), our hands-on scenarios and areas of emphasis are always different. We may focus on air monitoring during one training, decontamination techniques the next, then switch it up and stress the importance of proper research and documentation. We use the resources available at the customer’s site (mobile apps or software, chemical SDSs or proprietary information from the organization’s research and development lab) to make sure students have the most accurate and up-to-date information available. We ensure students understand the chemistry behind the hazmat response, rather than getting tunnel vision and immediately trying to figure out how to stop the leak. Students evaluate various situations, including potential reactions with other chemicals in the nearby area, worst-case scenarios dependent upon the current weather conditions.

We also rotate all students around during the scenarios and run multiple evolutions to ensure everyone gets an opportunity to perform the various tasks, which also allows us to properly evaluate their competency in those respective areas. If we see a student struggling, we try to let the other members of the hazmat team assist so they can develop leadership skills within their own organization. If the other team members are unable to help, we simply call a timeout, huddle up, and discuss the current situation. I live by the phrase “train like your life depends on it, because it does”. This helps us communicate the level of dedication required during training exercises.

What’s the key to best preparing responders to handle real scenarios outside of the controlled training environment?

Hazmat emergencies are very dynamic. While many acknowledge that there are no “textbook” situations, we often fall into the trap of relying on textbook information. We become familiar with a chemical’s flammability range, but fail to understand that the flammability range is based on standard temperature and pressure, so as temperature and atmospheric pressure fluctuates, so does the chemical’s flammability range, vapor pressure and instability.

To overcome this level of complacency, we often throw obstacles into the scenario, based on the student’s level of experience. We ensure we don’t overwhelm the students, but emphasize the importance of critical thinking in the middle of the hot zone.

Hazmat technicians and specialists need to understand that hazmat responses involve countless variables, which we try to interject during the hands-on scenarios. We continuously monitor the team members during all evolutions to see what is working well for them, while also looking for opportunities to safely and comfortably cause them to change plans. This may involve a simulated secondary leak, an unidentified chemical reaction that takes place, or a situation involving chemical degradation and/or penetration through the responder’s PPE.

What is your biggest obstacle when conducting hazmat training?

Things don’t always go as planned, which is what has always kept me on my toes when dealing with hazardous materials. As the old adage goes, “Plan for the worst, hope for the best”. We have to plan for our incident action plans to not go 100% the way we intended. Weather conditions change, members of hazmat teams come and go, and chemical spills, leaks and releases occur in different locations every time. We do our best to always prepare for multiple scenarios involving varying levels of experience and competence. However, as mentioned, we have to be able to adjust on the go to ensure the students get a thorough, informative and realistic training that will help them become a better responder.

What wicked training problem keeps you up at night?

When dealing with industrial hazmat teams, it’s often more difficult to emphasize the level of urgency that is needed when compared to firefighters and other professionals who do it on a daily basis. Many of the industrial hazmat teams consist of facility maintenance, operations and other individuals with varying levels of experience. Some team members are on the team voluntarily, whereas others are forced to be on the team based on what role they serve within the organization. Having team members that don’t necessarily want to be there creates an additional struggle that must be addressed when attempting to facilitate effective training evolutions, whether it be a tabletop exercise, classroom discussion or hands-on scenario.

What would it take to solve it?

This issue stems from an organization’s culture and level of planning. If complacency is allowed to float freely through all levels of a company, then that will become the norm. Supervisors need to take training seriously and get in the mentality of training like you respond. Many hazmat team members are worried about the “what’s in it for me” factor, so we can’t treat all personnel the same.

Find out what they enjoy doing and build on that. While I always rotate everyone to different roles within a training exercise (entry team, decon, safety officer, etc.), I also ensure I understand each person’s strengths and weaknesses. If you have a member of the team who is very analytical with a chemical engineering background, maybe they are best suited for a role in planning or research. If someone is mechanically inclined, put them on the entry team so that they can replace the failed diaphragm or damaged hose with ease. You can always build others up, but you have to know your resources and plug them in accordingly.

What devices do you rely on most for realistic training?

I use as much of the customer’s equipment as possible so that they become familiar and comfortable with their SCBAs, suits, metering equipment, etc. There’s no sense in having them learn how to use a meter that they may not ever use in the future. That said, we always bring a variety of equipment to the classroom and let them evaluate what is best for their site-specific hazards. We are currently in talks with HazSim to purchase one of their units to take our training to the next level. This will allow us to provide real-time readings on the gas meter, rather than having to place signs or verbally tell the responders what readings they would be getting during the scenarios.

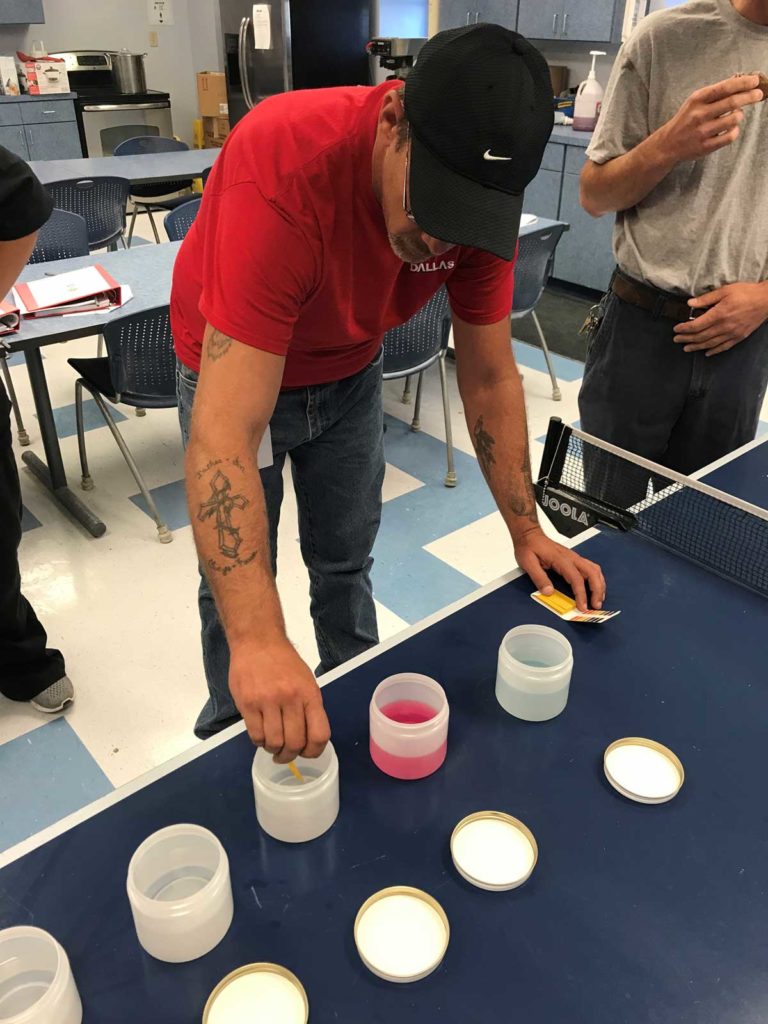

In addition, we add various visual and audible effects to the training. If the company uses a mobile app for communicating emergencies, we have them send out a realistic alert to begin the training evolutions. We use smoke machines and liquid dyes to create scenarios that look and feel real, compared to simply pouring out some water on the ground and telling them it’s sulfuric acid.

During the classroom portion, we have a handful of skills that we can demonstrate and let the students attempt, such as using gas meters with different technologies (catalytic bead vs. IR sensors), colorimetric (Drager) tubes, and pH test strips. We use controlled chemical scenarios in the classroom to allow them to understand the chemical hazards while not being rushed or feeling pressured like they may be during a real scenario.

How, if at all, do you alter training for new responders versus seasoned veterans?

Our classroom session is always mixed with varying levels of experience, which helps facilitate some great discussions. New responders tend to ask more questions and want to understand, which allows me to lean on the seasoned veterans for advice based on their experience. I’ll always add my thoughts on it, but I love seeing the discussion take place amongst the employees so that they can ask their own questions and determine their own answers.

When it comes to hands-on scenarios or tabletop exercises, we always pair a new responder up with a more experienced team member. If we have a large number of new people, we try to conduct a dry-run exercise where we walk and talk them through the response step-by-step. We try to expose the new people to various roles without overwhelming them. We ensure that they go at their own pace and perform the tasks based on their comfort level. If there’s something they don’t like doing, during the training is when we want to find that out.

If it’s mostly experienced people, we can usually give them a scenario and let them come up with their own game plan. We will give them the initial boost to get the scenario started, but then we try to take a hands-off approach so that we can thoroughly evaluate their skills and competencies while not being guided.

How do you keep the classroom portion of hazmat training fresh?

It’s all about making it relatable and as site-specific as possible. If I’m teaching at an organization that receives all their chemical shipments via cargo tanks, it doesn’t benefit me or them to show videos and spend a lot of time discussing how to respond to railcars. I enjoy sharing my ideas and thoughts with others so that we can mutually benefit one another, so attending various professional development and refresher courses across the country allows me to gain new ideas from other instructors. I don’t claim to know everything (and never will). So, I take advantage of my opportunities to be on the IHMM and HazMat Society committees to find new training materials, stay up-to-date on current trends and hazards, and determine what works best for the customer.

I change every presentation based on the customer’s site-specific hazards and organizational needs. While I ensure I cover the minimum topics and competencies outlined in applicable OSHA and NFPA standards, I change the presentation up every time to ensure they aren’t able to teach it to me. The chemical industry, as a whole, is continuously changing with companies trying to produce better, more efficient chemicals for a lower price. Sometimes that involves creating additional or new hazards, so it’s my responsibility to be knowledgeable of the current industry and regulatory changes and trends so that I can pass that information along to the students.

What’s the optimum class size and why?

I try to have a class size of around 10 people per class. This allows us to fill all the required roles without having too many people just standing around waiting with their hands in their pockets. If we get a larger group of employees, we can either bring in a second instructor to run a separate scenario or we can just break it into multiple classes.

What problem has changed how you teach?

As much as we say we’re not complacent, we are — all of us. Knowing that, it’s a matter of finding out where their complacencies are and re-igniting that fire. Since 2017, approximately 67% of the fatalities involving confined spaces have been contributed to atmospheric hazards and/or lack of proper air monitoring. Due to this, air monitoring has been a pet peeve of mine and has caused me to notice how much people don’t know about their own gas meters. Early in my career at the fire department, I noticed that many of my fellow firefighters had no idea what a T90 or T50 response time was, which made me question how competent we (first responders) really were.

Whether it’s inside a house fire, inside a confined space or downrange in the hot zone, understanding your own equipment is paramount. Each class I conduct is focused on understanding the ins and outs of the customer’s site-specific equipment. Whether it’s knowing your meter’s cross-sensitivities and response times or knowing how to determine which ventilation fan is intrinsically safe, we have to know what we have and know how to use it properly. Failing to do so only ends in disaster at the job site.

What role does technology play in how you teach hazmat and what do you think the future holds for it?

Organizations now have access to mass communication mobile apps and can provide instant notifications of the emergency and other relevant details within seconds, similar to Who’s Responding, CADPage and other mobile apps used by fire departments across the country. While it may take a little extra time to type the initial report, it prevents miscommunications associated with radio communications.

In addition, innovative software and technology, like HazSim, allows our air-monitoring scenarios to be as realistic as possible without exposing responders to dangerous concentrations of hazardous materials. The future will only get better in terms of responder safety, with the introduction of drones at hazmat scenes to view downrange situations prior to the entry team even being suited up. As long as the industry (both private and public sector) are receptive to it, we are going to make training even more realistic in the future with reduced exposure to actual hazards, allowing for a safer (yet still effective) hazmat response.

What role does NFPA and OSHA play in hazmat training?

Many organizations are unaware of how voluntary, national consensus standards, such as NFPA 472, can apply to their industrial hazmat team’s response. Organizations look at OSHA’s HAZWOPER standard (1910.120) and think that as long as they check all of the boxes on that, then they’re good to go. They fail to acknowledge that OSHA’s standards are the bare minimum and often don’t mention any required competencies, such as those listed in NFPA standards. Industrial organizations fail to ask themselves “How can we get better?” instead of “How do we remain compliant?”, which can make a world of difference.